The Future Is now.

Capture more profit with direct to garment printing.

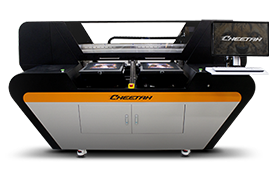

Award-Winning Line of Direct to Garment Printers

Request a Free Demo Today!

It’s All in the Details.

Request a Free Demo Today!

While other DTG printers suffer from clogged print heads, slow printing processes, component breakdowns, and poor color matching, our printers are reliable and offer unique features and systems that significantly boost productivity.

Choose a Printer

Freejet 330TX

The 330TX is the ideal solution for a start-up t-shirt business, a garment decorator looking to supplement their existing business, or a commercial print business seeking to add new product lines.

FreeJet 330TX Plus

The FreeJet 330TX Plus can print on dark polyester, cotton, and poly/cotton blends with our specially formulated inks. The Plus model also expands on the 330TX with additional features including automatic laser height adjustment, white ink circulation, and higher print resolution.

| Printer Model | FreeJet 330TX | FreeJet 330TX Plus | Cheetah |

|---|---|---|---|

| Print area dimensions | 12.5” x 22”

additional platen sizes available

|

12.5” x 22”

additional platen sizes available

|

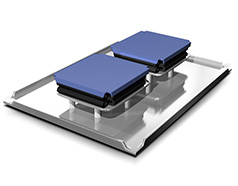

Two 16” x 20” Platens |

| Printing substrates | 100% cotton and cotton blends |

Cotton, Cotton/Poly Blends, 100% Polyester (all colors) |

Cotton, Cotton/Poly Blends, 100% Polyester (all colors) |

| Colors | 8 Channels: CMYK + WWWW or CMYK + CMYK |

8 Channels: CMYK + WWWW or CMYK + CMYK |

Green, Orange, Yellow, Magenta, Cyan, Black, White1, White2 |

| Print direction | Bi-directional/unidirectional | Bi-directional/unidirectional | Uni/Bi Directional Printing |

| Ink Types | Direct Ink powered by DuPont Artistritm |

Direct Ink Gamut Plus Water Based Pigment Inks |

Direct Ink Industrial Series Water Based Pigment Inks |

| RIP software | DirectRip Included | DirectRip Included | DirectRip with Color iOs |

| Software requirements | Windows® 7, XP, Vista, Mac using parallels or similar emulator |

Windows® 7, XP, Vista, Mac using parallels or similar emulator |

Windows 10 PC Included |

| Garment Detection | Automatic, up to 5” | Automatic Adjustment using optical sensor up to 5 inches | Automatic Height - Garment Detection System |

| Dimensions | 25” Width x 42” Length x 18” Height |

25” Width x 42” Length x 18” Height |

10ft Width x 6ft Length x 6ft Height |

| Weight | 150 lbs. | 150 lbs. | 2900 lbs. |

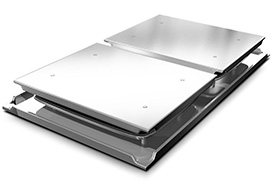

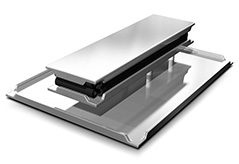

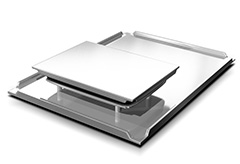

Expand Your Print Area

Looking for a specialized platen for your shop? The FreeJet 330TX and FreeJet 330TX Plus models have interchangeable platens to cover a variety of print areas and surfaces.

Request a Free Demo Today!

See What Our Printers Can Do!