The FreeJet series of Direct to Garment printers are the only printers in the industry to use the tried and true “Wet Capping” system. The most important factor with digital garment printers is how white ink is controlled. Because white ink is a heavy pigment it will settle in the printer and over time cause clogging or poor print performance of the print head. The print head is the most valuable part of the printer and a clogged or poor performing head is just not an option. Some machines circulate the white ink to help separation but depend on constant print head cleans to keep the nozzles from clogging. This process wastes a lot of ink and is only dependable for a limited amount of time.

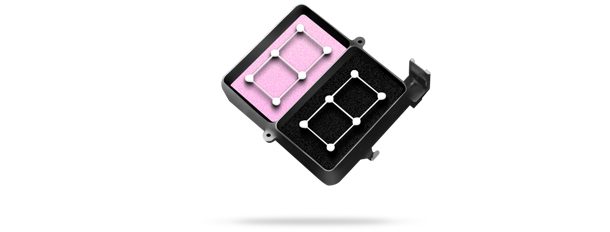

Wet Capping is an integrated system that allows you to keep the print head soaking in a cleaning solution when not in use. When you are done with printing the head is simply wet capped and the machine is turned off. The printer can sit for 30 days trouble free. That is not the only benefit though, the fact that the printer is turned off relates to no routine cleans wasting ink and costing you money when the machine is not in use. As most machines sit unused the ink flow will become harder and harder to establish when used again. A lot of time can be spent purging and cleaning before the printer is ready to start printing. Because Wet Capping keeps the print head wet you are never spending ink and time trying to establish ink flow. It does not matter if it has been a day, a week or even a month with Wet Capping the print head is always fresh and ready to go.