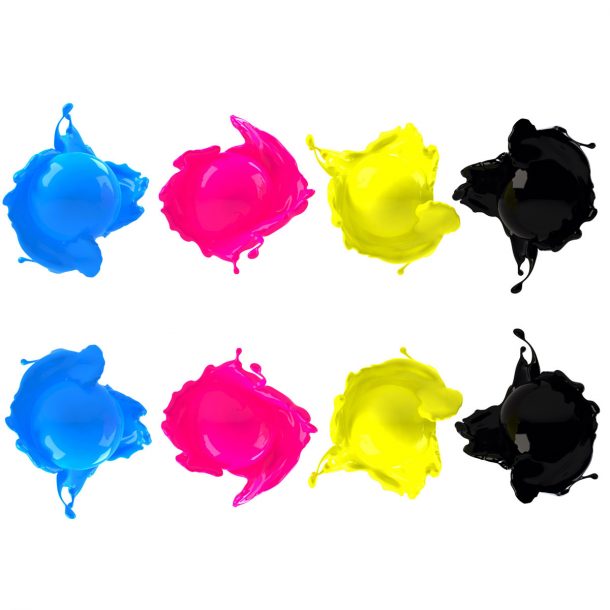

There has been a lot of videos surfacing lately about super high prints per hour on white shirts. This is something that has been possible for a long time and is being brought back to light. First of all most printers can be set up to run dual CMKY and remove the white. This is actually how printers first came while white ink was being introduced and perfected. When you add dual CMYK to your printer you can change the resolution to 720×720 from the standard 1440×1440 setting. At 720 x 720 the printer is much faster but puts down less ink but because you are now running twice the CMYK you are getting more ink to compensate.

Keep in mind this is just for white shirts or prints not requiring white ink. A few more steps can be taken to increase production like a second heat press. At the speed you will be printing you don’t want to be waiting on a heat press. By having a second press you will be cutting out any waiting and have a constant flow. The second factor is a printer that has a removable platen. Having a second platen to load while another shirt is printing is defiantly key to adding more speed. The final component would be hustle, if you can keep up the pace you could be in the 60 plus per hour count on printed shirts.

At the pace of 60 plus shirts an hour you can now really compete with screen printing, today’s lower ink costs also contribute to this. If you can find the business with light garments it can be done. Don’t get this confused with reality though, dark garments and having to pretreat garments is a big part of DTG printing. Having to dedicate your machine to just white and light garments is going to limit your services so you will need to have or get the work to make this dual CMYK set up work for you. You will need to flush your system each time you change back and forth. The print quality of a dual CMYK machine is not as good as a pretreated shirt printed at 1440, it’s not bad but you can see the difference for sure. If you are looking for a DTG printer and think you are going to print 60 or more shirts an hour you need to understand. This is just a way you can maximize your white shirt printing if you have the work to do so printing only light garments. When it comes to light garments you do not need to pretreat, you can do double pass print and get a better print. This is adding more time though. You will see your print quality the best at standard 1440×1440 pretreated, not as good but better with 2 pass cmyk only and then not too bad at single pass dual cmyk. So please keep in mind doing this is for high production on light garments only.

The thing I like the most about this is the fact everyone is pushing the limits to show what can be done. DTG is really getting so much better by the day. It is great to see our industry showing that DTG is no longer a limited production option. Where there is a will there is a way.